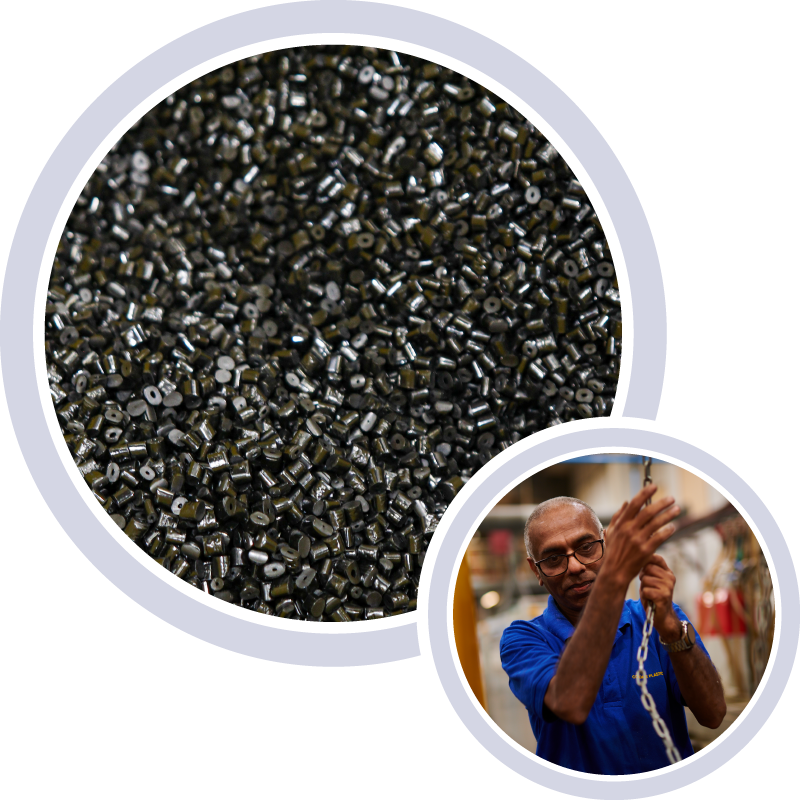

As a specialist thermoplastic extrusion manufacturer, the team here are able to produce bespoke extrusions from our West Sussex factory in a range of different plastic extrusion materials. These extrusion materials include conventional plastics like Rigid PVC (uPVC), Flexible PVC, ABS, Polypropylene, Polyethylene, EVA and HIPS. We also deal with more specialised engineering plastic materials like ASA, PC/ABS, Polycarbonate, PETG, Noryl, Impact Acrylic, Acetal, Nylon, Styrolux, Styrosun and many more. As well as rigid materials, we also work with flexible plastic materials to offer extrusions for every need.

What should I consider when selecting plastic extrusion materials?

The choice of thermoplastic material needs to be carefully weighed up depending on the application. A number of factors need to be considered such as; interior or exterior use, impact strength, low/high temperature resistance and degree of clarity on clear materials. It’s also important to consider the hardness/softness of material, electrical properties, fire retardant properties and halogen free properties. Some plastic extrusion materials need to be chemical or temperature resistant, while others may need to have adhesive properties. Our experts will be able to advise on the best solution for your needs as our plastic extrusions are custom made in our factory.

We source all our plastic extrusion materials from the best quality sources and are always trialling new extrusion materials. Many of our products are made from recycled plastic extrusion materials and are designed to have a long life cycle. Our thermoplastic materials are all high quality, which results in a better, longer lasting extrusion. Our expert team will oversee the entire extrusion process, from initial design and inquiry through to the manufacturing and delivery of your extrusions. Most of our plastic extrusion materials are able to be provided in a choice of colours, so discuss your bespoke order with our plastic specialists today!

View our materials selection table to select the best material to meet your requirements or, if you would like specialist advice on material selection, call our technical sales team on +44 (0)1342 312 714 or complete our enquiry form.

Virtual Tour Video

Explore a diverse range of materials to suit your needs

Advice on your initial extrusion design

An extensive range of colours and colour matching

A range of surface finishes to enhance product appeal and use