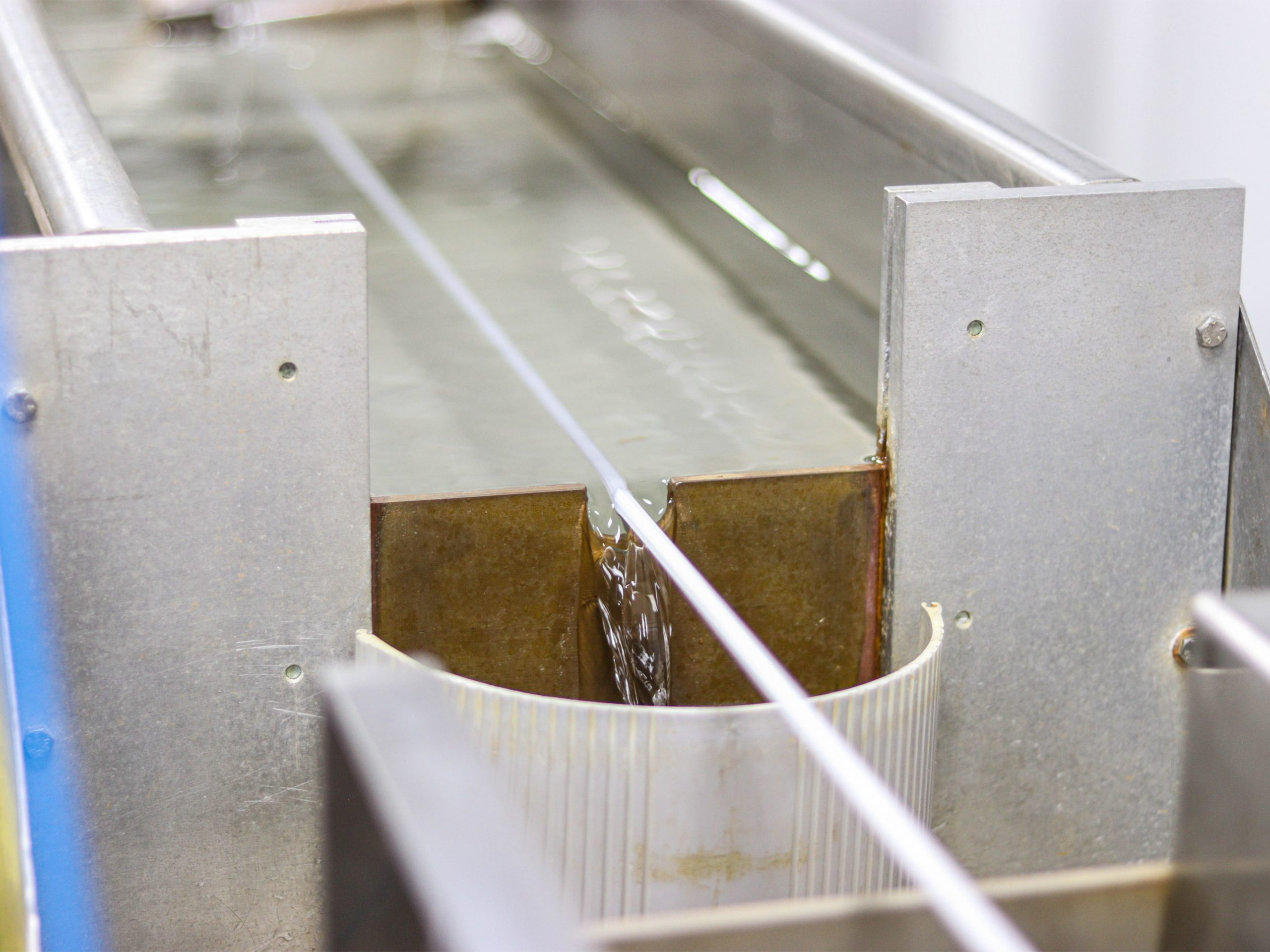

Plastic extrusion, a remarkable manufacturing process, forms the backbone of Condale Plastics’ diverse offerings. This innovative method involves shaping raw thermoplastic materials into continuous profiles of various shapes and sizes.

During extrusion, the plastic is heated, softened, and then forced through a die to produce the desired cross-sectional shape. The resultant plastic profiles boast exceptional design flexibility, durability, and cost-effectiveness, making them the ideal choice for a myriad of applications across industries. From building and construction to medical devices, lighting fixtures to sports equipment, plastic extrusions have paved the way for boundless possibilities.

Let’s explore the full potential of this remarkable technique and discover the projects and applications where Condale Plastics’ extrusions excel.

Materials Handling

Plastic extrusions have revolutionised materials handling, particularly in warehouses, where they serve as robust and impact-resistant protection barriers. Their design flexibility allows for customised barriers that fit specific warehouse spaces, while their lightweight nature ensures easy installation and adaptability. The durability of plastic extrusions guarantees prolonged protection, reducing maintenance costs and downtime. Additionally, their high visibility colours enhance safety awareness, making them invaluable in warehouse environments.

Lighting

The lighting industry embraces plastic extrusions for creating innovative lighting fixtures and diffusers. The ease of extruding complex shapes and the ability to incorporate LED strips or other lighting elements make extrusions an efficient and creative solution. Additionally, the high clarity of plastics enhances the performance of lighting applications.

Building and Construction

Plastic extrusions find an extensive range of applications in the building and construction industry. They are commonly used for window and door frames, roofing, cladding, and fencing systems. The lightweight and durable nature of plastic extrusions make them an excellent choice for modern construction projects, where energy efficiency and sustainability are essential.

Engineering

In engineering applications, plastic extrusions play a pivotal role due to their adaptability and design flexibility. From intricate profiles for machinery components to custom-designed gaskets and seals, extruded plastic materials can meet diverse engineering requirements. Their ability to withstand harsh environments, chemicals, and UV exposure further enhances their appeal.

Horticulture

Agricultural and horticultural industries benefit from plastic extrusions for various purposes. They are widely used in greenhouse construction, irrigation systems, and protective edging. Plastic extrusions offer superior corrosion resistance and are easy to clean, making them an ideal choice for applications in humid and demanding environments.

Medical

Plastic extrusions have revolutionised the medical field, where precision and hygiene are paramount. They are commonly used for manufacturing medical tubing, catheters, and other disposable medical devices. The smooth surface finish of extrusions minimises the risk of bacterial growth, making them suitable for critical healthcare applications.

Office Furniture and Partitions

Extruded plastic profiles play a significant role in the production of office furniture and partitions. Their design versatility allows for customisable and aesthetically pleasing solutions, while the lightweight nature simplifies transportation and installation. Plastic extrusions also provide excellent acoustic and thermal insulation properties, enhancing office comfort.

Packaging Cores

Plastic extrusions are the ideal choice for manufacturing packaging cores, used in industries like textiles, films, and tapes. Their consistent dimensions and strength ensure the safe winding and unwinding of materials during production and transport. Additionally, the recyclability of plastics aligns with sustainable packaging practices.

Retail and Display

Retail environments often utilise plastic extrusions for shelving systems, display stands, and signage. The ability to produce eye-catching designs and colours, along with their durability, makes them an excellent choice for presenting products attractively. Plastic extrusions help create engaging retail displays that enhance the overall shopping experience.

Sports and Leisure

From sporting equipment components to leisure industry products, plastic extrusions offer practical and innovative solutions. Their lightweight nature benefits sports equipment, while their weather resistance makes them ideal for outdoor leisure applications like garden furniture, decking or trims on caravans.

Transport

Plastic extrusions play a vital role in the transportation industry, contributing to vehicle interior components, door seals, and exterior trims. Their high strength-to-weight ratio and resistance to chemicals and weather conditions ensure their longevity and reliability in the demanding transportation sector.

Exploring the Right Solution for You

Plastic extrusion has proven to be a game-changer across a multitude of industries, providing innovative solutions for diverse applications. Condale Plastics’ wide range of plastic extrusions offers unmatched design flexibility, durability, and cost-effectiveness for projects across a broad range of sectors. Embracing plastic extrusions unlocks a world of possibilities for businesses seeking to develop tailored solutions to create reliable products for their customers.